| It is currently Sat Apr 27, 2024 7:59 pm |

|

All times are UTC - 5 hours [ DST ] |

Using a FWD car motor and trans

Moderator: JeffClay

|

Page 1 of 2 |

[ 38 posts ] | Go to page 1, 2 Next |

|

| Author | Message | ||||

|---|---|---|---|---|---|

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| lngtrvl2332 |

|

||||

|

Joined: Sat May 29, 2010 12:20 pm Posts: 465 Location: Northwest Indiana |

|

||||

| Top | |

||||

| MartinB |

|

||||

|

Joined: Fri Jan 07, 2011 6:38 am Posts: 132 Location: Chichester UK |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| jesse |

|

|||||

Joined: Fri Nov 30, 2007 4:03 pm Posts: 3181 Location: leeds alabama |

|

|||||

| Top | |

|||||

| Andrew_Ha |

|

||||

Joined: Tue Mar 25, 2008 6:56 am Posts: 559 Location: EAST LIVERPOOL, OH |

|

||||

| Top | |

||||

| lngtrvl2332 |

|

||||

|

Joined: Sat May 29, 2010 12:20 pm Posts: 465 Location: Northwest Indiana |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| ImmortalSoul219 |

|

||||

|

Joined: Wed Dec 10, 2008 8:07 pm Posts: 603 Location: Lancaster, Pa |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| bradley59dzl |

|

||||

|

Joined: Sun Jun 22, 2008 4:06 pm Posts: 510 Location: enon valley(hillsville), pa |

|

||||

| Top | |

||||

| passat2800 |

|

||||

Joined: Mon Aug 10, 2009 11:33 am Posts: 1049 Location: Birmingham Alabama |

|

||||

| Top | |

||||

| MartinB |

|

||||

|

Joined: Fri Jan 07, 2011 6:38 am Posts: 132 Location: Chichester UK |

|

||||

| Top | |

||||

|

Page 1 of 2 |

[ 38 posts ] | Go to page 1, 2 Next |

|

All times are UTC - 5 hours [ DST ] |

Who is online |

Users browsing this forum: Bing [Bot] and 40 guests |

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot edit your posts in this forum You cannot delete your posts in this forum You cannot post attachments in this forum |

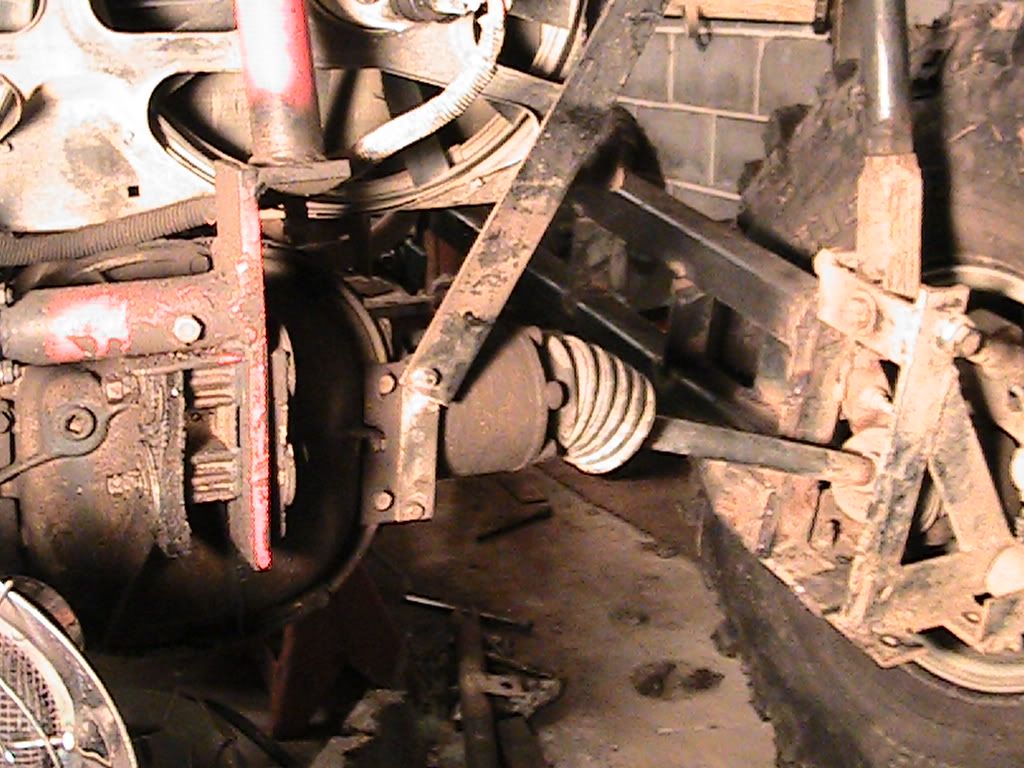

af spring also makes its own stop.Bad photo.

af spring also makes its own stop.Bad photo.  Sorry for the old mud in crud from last year. Here's how easy it is to put the car stuff on and they have given me absolutly NO trouble and STOP GREAT!The whole new trailing arm is mounted high and away from rocks and in CLOSE to the tire. Even better when the FAT 40 " goes on the same rim.

Sorry for the old mud in crud from last year. Here's how easy it is to put the car stuff on and they have given me absolutly NO trouble and STOP GREAT!The whole new trailing arm is mounted high and away from rocks and in CLOSE to the tire. Even better when the FAT 40 " goes on the same rim. This Carl. Chik out tis tar I built fer ol DD.I cut the welds outa an ole 16"trunk spare donut. sum peple cawlit a trunk spare, I calwlit a donut. mmhm.Din I mazured 6 spokes evenly going from the lug nut whole bofe ways. Then I spreadeded it out onis Isuzu hub witta brake a gone offit in to a star shape n wot not with tha lug nuts a titened.I tac weled it a time r 2.Then I spun it a time r 2 on his Isuzu spindle mounted in a viced. It wobbled a little so I re did it mmm.DD got up n spun and liked it so I weldeded it up fer em.He told me later I shoulda wore his welding shield.I walked off his porch got hirt again.mmhm

This Carl. Chik out tis tar I built fer ol DD.I cut the welds outa an ole 16"trunk spare donut. sum peple cawlit a trunk spare, I calwlit a donut. mmhm.Din I mazured 6 spokes evenly going from the lug nut whole bofe ways. Then I spreadeded it out onis Isuzu hub witta brake a gone offit in to a star shape n wot not with tha lug nuts a titened.I tac weled it a time r 2.Then I spun it a time r 2 on his Isuzu spindle mounted in a viced. It wobbled a little so I re did it mmm.DD got up n spun and liked it so I weldeded it up fer em.He told me later I shoulda wore his welding shield.I walked off his porch got hirt again.mmhm