That's interesting. My first thought is if they have enough articulation in them for what we do? My next concern would be with high horsepower-heavy weight buggys whether or not they would be subject to a thing called spline lock.

I was talking with some buggy gurus out in Cali. and I told them about me buying a set of High Angel Half shafts.

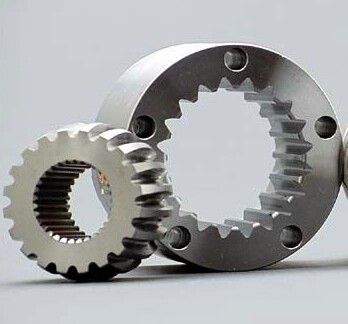

Their first reaction was that I made a mistake and they told me about some guys doing some desert racing that tried them. They were running 500HP 3000LB cars and they were ripping trailing arms off the back of the cars. What the figured out was the splines connecting both halves of the axle together was binding when the car was landing under heave torque load. Since the splines didn't move when the car landed because of the high hp/heavy car load, the axle acted as if it was solid, no slip, and forced the trailing arms out away from the center of the car ripping the inboard mounts right off the housing.

After some conversation I asked what they thought of a light weight car (1500lb) and a comparably lower HP (170hp) using them? All of them said I shouldn't have any problems.

I guess it's like everything else, let someone else be the crash test dummy and see if they have any problems with them. Give them some time if they work, you'll know soon enough. If they don't, you'll never hear about them again.